Get Superior Control with Membrane Switch for Electronics

Get Superior Control with Membrane Switch for Electronics

Blog Article

Discover the Versatile Uses of Membrane Layer Change in Modern Electronics

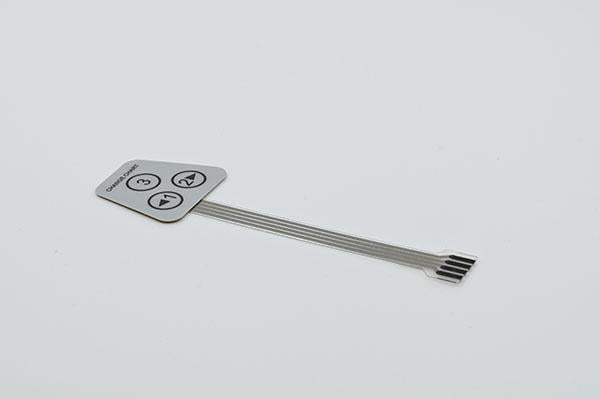

In the realm of modern-day electronics, the application of membrane layer buttons is incredibly substantial, spanning from sleek customer devices to critical medical tools. These thin, flexible user interfaces not only streamline gadget operation with their responsive responsiveness however additionally considerably improve resilience by withstanding ecological hazards like dampness and dirt. As markets proceed to develop, the assimilation of membrane layer buttons in equipment design is critical, encouraging not just to fulfill yet surpass the rigorous needs of both functionality and visual allure. Discover extra regarding just how these elements are forming the future of technology.

Exploring the Function of Membrane Changes in Customer Electronics

Why are membrane layer switches so prevalent in consumer electronics? Membrane switches are economical to make, making them an eye-catching alternative for high-volume manufacturing regular in customer electronic devices.

Moreover, these buttons are understood for their longevity and reduced maintenance. They are immune to moisture, dirt, and dust, which improves the long life of the digital gadgets they are utilized in. This reliability is essential in everyday consumer items that undertake regular use. Additionally, their flexibility in design makes it possible for modification in visual appeals and performance, catering to the certain requirements of different digital gadgets. From microwave to remote controls, membrane layer switches provide a practical, straightforward user interface that supports the vibrant nature of consumer electronics.

Membrane Layer Switches Over in Medical Tools: Enhancing User User Interfaces

Membrane buttons also play a considerable role in the world of medical devices, where they improve interface with their unique advantages. These switches are specifically valued for their dependability and convenience of sanitation, crucial in medical care environments where tidiness is paramount. The smooth, closed surface area of membrane switches over permits very easy disinfection, lessening the threat of contamination and spread of pathogens. Their style adaptability suits the ergonomic and visual requirements of clinical tools, making gadgets extra intuitive and available for health care experts.

Membrane layer switches also contribute to the link resilience of medical tools. Their resistance to fluids and impurities ensures that crucial equipment continues to be functional in numerous medical setups, including surgeries where exposure to liquids is common. This longevity, coupled with responsive click this comments and low-profile layout, makes membrane switches an integral element in boosting the performance and safety of medical gadget interfaces.

The Impact of Membrane Layer Changes on Industrial Tools Style

In the world of industrial devices style, the incorporation of membrane switches has marked a significant evolution. The slim profile of membrane layer switches over allows for even more compact maker styles, while their resistance to water, dirt, and chemical pollutants makes them suitable for industrial settings.

Additionally, the customizability of membrane switches over makes it possible for designers to integrate certain tactile comments and visual overlays that boost the customer experience and increase effectiveness. This integration supports operators in achieving precision control over intricate equipment. The general effect is a significant improvement in the functionality, reliability, and user-friendliness of commercial devices, lining up with the raising needs for technical development and operational performance in modern-day markets.

Conclusion

Membrane layer switches have actually revolutionized modern-day electronic devices, using sleek, sturdy, and customizable interfaces across different sectors. Membrane Switch. In customer electronic devices, they enhance the visual and performance of tools. Medical industries take advantage of their trusted, easy to use controls, vital for delicate settings. In a similar way, industrial applications value their durability and efficiency. This innovation not only meets the requiring problems of various areas yet likewise substantially enhances customer experience, making membrane changes a keystone of contemporary electronic design.

In the world of modern-day electronics, the application of membrane switches is remarkably considerable, spanning from streamlined consumer devices to crucial medical gadgets.Why are membrane changes so widespread in customer electronic devices? Membrane buttons are affordable to make, making them an attractive alternative for high-volume manufacturing regular in consumer electronics. From microwave go to my site ovens to remote controls, membrane buttons give a sensible, straightforward user interface that supports the dynamic nature of consumer electronics.

Report this page