Key Considerations When Choosing Industrial Scales for Your Warehouse Operations

Key Considerations When Choosing Industrial Scales for Your Warehouse Operations

Blog Article

Why to Choose Industrial Scales for Accurate Weight Measurement in Different Industries

In an age where accuracy is vital, the option of commercial scales for exact weight measurement plays an important role across varied fields. These ranges not just boost operational efficiency however additionally make certain compliance with regulatory requirements, impacting every little thing from production to shipping.

Relevance of Accurate Weight Dimension

In the realm of commercial procedures, the value of exact weight measurement can not be overemphasized. Specific weight measurement is foundational throughout various fields, affecting both operational efficiency and product high quality - Industrial Scales. It acts as an essential variable in stock management, guaranteeing that materials are effectively accounted for, therefore minimizing waste and reducing costs

In production, exact weight measurement straight influences production procedures. Anomalies in weight can result in low-grade items or excessive resource appropriation, affecting total productivity. Additionally, in sectors such as drugs and food manufacturing, adherence to rigorous weight requirements is essential for governing conformity and customer security.

In addition, exact weight measurements promote effective logistics and supply chain monitoring. Appropriately weighed deliveries make sure that transportation prices are optimized and that stock degrees are preserved precisely, thus avoiding supply scarcities or overstock circumstances.

Kinds of Industrial Scales

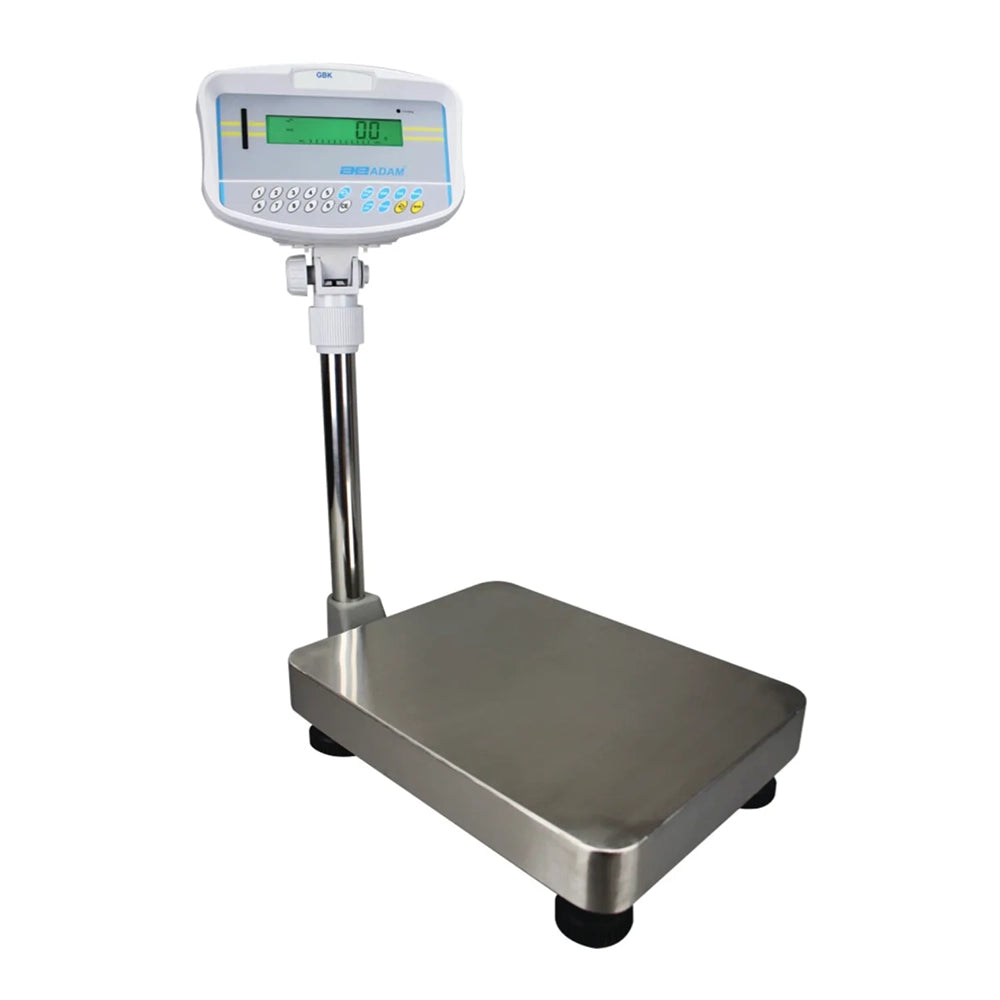

A wide range of commercial ranges are offered, each created to meet details measurement requires across varied markets. Usual types consist of flooring ranges, which are durable and appropriate for weighing large things or pallets in warehouses and distribution facilities. Bench scales are smaller sized and suitable for lighter products, typically used in retail setups or manufacturing for specific portion control.

An additional category is portable scales, which supply the adaptability to be relocated quickly around task sites, making them excellent for area procedures or short-lived arrangements. Precision scales, on the other hand, are made for high accuracy and are regularly utilized in laboratories and high quality control environments.

Tons cells are vital elements in numerous industrial scales, transforming force right into an electrical signal for accurate readings. In addition, truck scales provide the ways to consider hefty lorries and their loads, making certain conformity with laws and maximizing logistics.

Last but not least, checkweighers immediately contrast the weight of items against pre-programmed limitations, enhancing quality assurance in production lines (Industrial Scales). Each kind of industrial scale serves a distinct function, accommodating the certain needs of markets such as production, logistics, food handling, and drugs

Benefits of Utilizing Industrial Scales

Consistently using industrial ranges uses substantial advantages throughout various fields. One of the key benefits is enhanced precision in weight dimension, which is essential for maintaining top quality requirements and regulatory conformity. Precise measurements avoid costly errors in manufacturing, supply, and delivery administration, inevitably leading to raised operational effectiveness.

Furthermore, industrial scales are made for durability and toughness, permitting them to stand up to extreme settings generally discovered in production and warehousing. This resilience makes sure a lengthy life expectancy, minimizing the demand for frequent replacements and maintenance expenses.

In addition, using commercial ranges boosts security and reduces waste. By guaranteeing that products are weighed properly, business can avoid straining automobiles, which can result in accidents and fines.

Applications Across Various Industries

Industrial scales play a pivotal function in countless industries, including production, logistics, food handling, and pharmaceuticals. In manufacturing, these scales are crucial for ensuring that raw materials are determined properly, consequently keeping product find more top quality and consistency (Industrial Scales). Accuracy in weight measurement directly affects manufacturing effectiveness and price administration

In logistics, commercial scales facilitate the exact evaluating of deliveries, which is crucial for sticking to optimizing and delivering policies freight costs. Exact weight data aids simplify procedures and boosts supply chain administration.

The food handling market depends heavily on commercial ranges for compliance with health and wellness and security laws. They are utilized to weigh components precisely, making sure that solutions fulfill both quality criteria and lawful requirements. This is important not only for consumer safety and security yet likewise for maintaining brand integrity.

Pharmaceutical firms utilize commercial scales to make certain precise dosages in medicine production, where even the least deviation can have considerable repercussions. Compliance with rigorous regulative requirements makes precise weight dimension critical in this field.

## Factors to Take Into Consideration When Selecting Scales

Picking the right range for specific applications requires cautious consideration of several factors. Primarily, the capacity of the scale is important; it needs to accommodate the optimum weight of the items being determined without surpassing its restrictions. In addition, the readability, or smallest increment the range can accurately display, is crucial for precision, specifically in sectors where weight inconsistencies can lead to significant monetary losses or safety concerns.

Ecological problems also play a considerable role in range choice. For example, scales made use Homepage of in harsh or damp settings might require specialized materials to make sure toughness. Transportability may be crucial in specific applications, demanding light-weight and battery-operated models.

Final Thought

In verdict, the option of commercial ranges is crucial for ensuring precise weight dimension across diverse markets. Their ability to give specific analyses not only improves operational efficiency but likewise sustains governing conformity and supply management. The adaptability and sturdiness of these ranges facilitate their application in various industries, ultimately adding to cost decrease and improved product high quality. Therefore, investing in high-quality industrial scales is necessary for organizations aiming to keep high standards and make the most of productivity.

Report this page